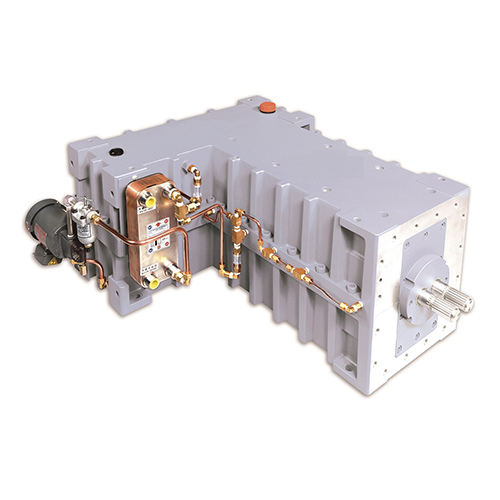

Gear Box for Parallel / Conical & Co-rotating / Counter-rotating Twin Screw Extruders

Categories : Gearboxes

Equipped with precise gearbox newly developed by ourselves,our extruder features improved performance, high efficiency, and extended service life. We also produce and export various kinds of extruding machine parts and components. Contact us for more information.

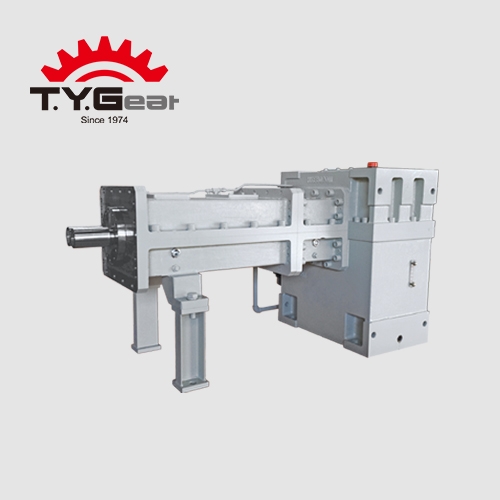

Twin Screw Extruder Co-Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

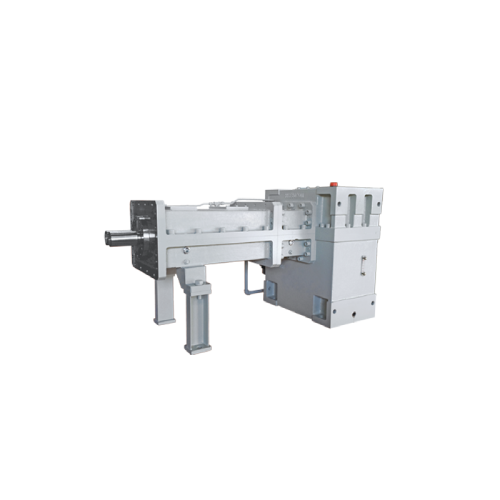

Twin Screw Extruder - Counter Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.